WOOMERAROBOTIC

INSP

WOOMERAROBOTIC

INSP

RELEASED

ECTION–MAYFIELD

TRIPREPORT

BY

28thMay–1stJune

ARPANSA

UNDER

FOI

FEBRUARY

2019

ErinMcCol

CSIROData61|1TechnologyCourt,Pullenvale,QLD

Introduction

TheMayfieldtriptotheWoomeraTestrange,28thMay–1stJune,wasaninitial

investigativetripfortheData61Roboticsteam.

Aim

Theaimofthistripwastotoevaluatetheenvironmentandtestanelementarypallet

inspectionrobot.Thisallowedustoevaluatethefunctionalityoftheplatformwithrespect

RELEASED

tomobilityandsafetythroughtheenvironment,allowingustobetterunderstandthe

challengesandevaluatetherobotdesignsothatimprovementscanbemadeforfuture

phases.

Scope

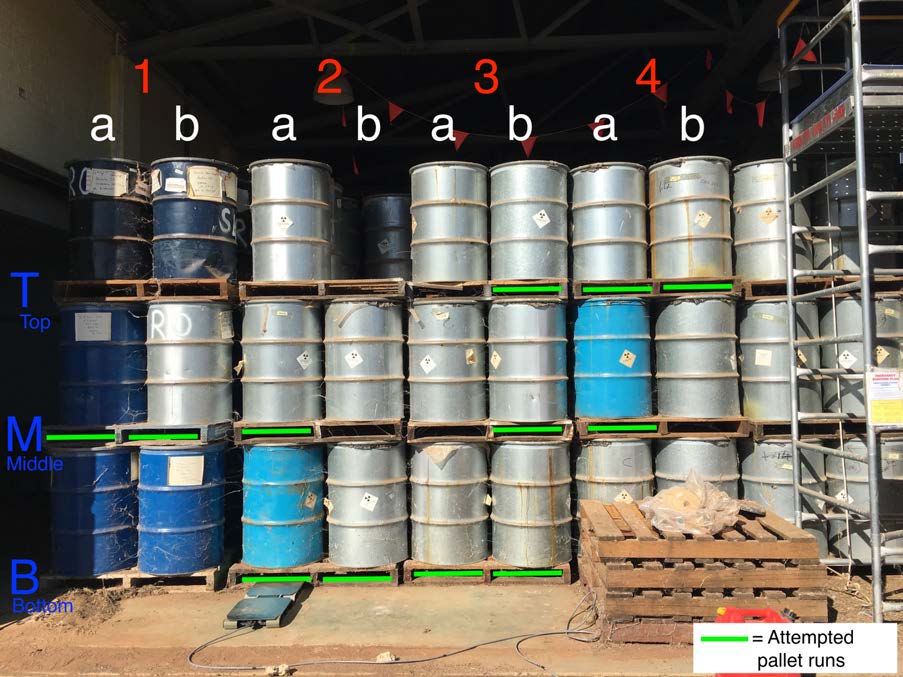

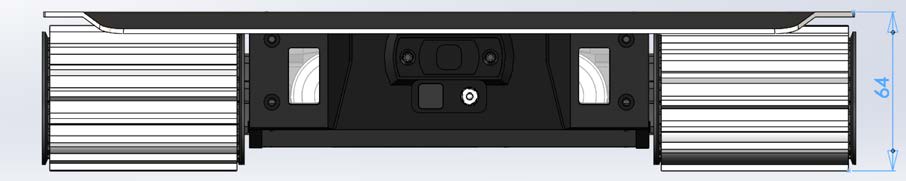

Giventheorientationofthepalletsinthehanger,asubsetofpalletrunswereinvestigated

duringthisfieldtrip.Thesepalletswerethoseaccessiblethroughbaydoor1asindicatedin

BY

Figure1.Therunswerelabelledfollowingtheco-ordinatesystemshowninFigure1.

ARPANSA

Thescopeofthisworkwasprimarilytestingtheabilityofthepalletrobottomove

consistentlyandeffectivelythroughtheenvironment.Therefore,itwasprincipallyatestof

thechosenmechanicaldesignandthepowerandcontrolsystems.Anominalsensing

packagewasincludedtoassistinthenavigation,thisincludeda

singlefrontfacingcamera,

lightingandasmalllowcostdepthsensor.Whilstthescopeofthistripwasnotfocused

aroundsensinganddatagatheringthesesensorsdidallowforsomedatacaptureduringthe

UNDER

testruns.

FOI

FEBRUARY

2019

Figure1–Locationandco-ordinatesystemofpalletrunsaccessedduringtrial

PalletRobotDesign

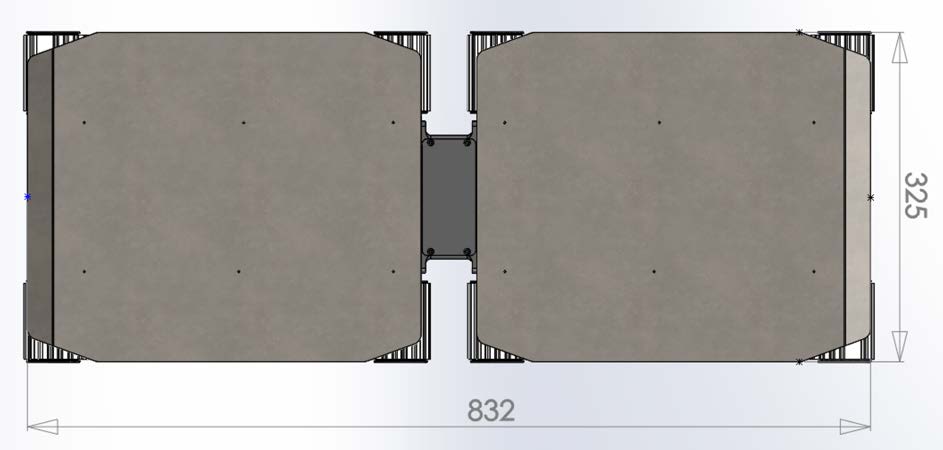

Aminimalviableplatformwasdesignedforthistrip,toassesstheplatformsenvironmental

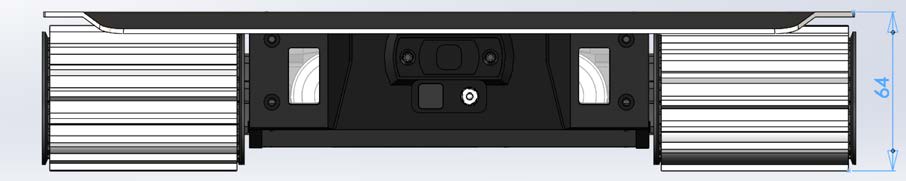

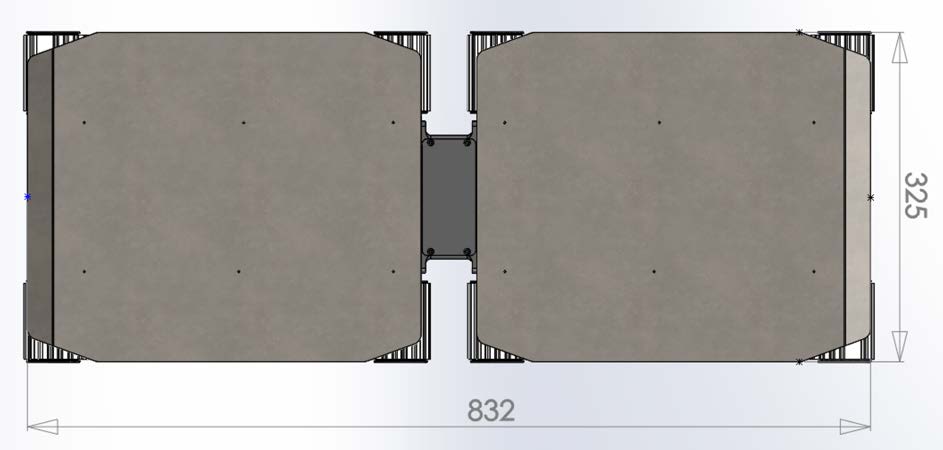

suitability.ThepalletrobotusedforthistestingisshowinFigure2,itconsistsoftwohalves

butwithatotallengthof832mm,atotalwidthof325mmand64mmheightasdefinedin

theFiguresonthetitlepage.

Thefrontsectionincludeslighting,acamera,anddepthsensor(Figure2a),Thebackhasthe

RELEASED

connectionpointforthetetherandpowerswitch(Figure2c).Thetethercarries110Vpower

andcommunicationoverEthernet,allcontrolisdoneoffboardusingtheRobotoperating

system(ROS)onaLinuxlaptop,controlledwithagamepadcontroller.Internallythereisa

voltageregulator(110và12V),2xmotorcontrollers,and4motors.Thetetheralsoactsas

aretrievalsystemshouldtherobotgetstuck.

BY ARPANSA

Figure2a:Thefrontoftherobot.ThewhiterectanglesdirectlynexttothetracksoneachsideareLED

lightswithaplasticcover.Thecentreuppercameraisastandardvideocamera.Thecentrelowercamera

isatime-of-flight3Dcamera-thepicoflexx. UNDER

FOI

FEBRUARY

Figure2b:Thecompleterobotwithoutatetherattached.Thefronthalfoftherobot(withthecameras)is

ontherightsideoftheimage.Theleftsideoftheimageisthebackhalfwiththetetherconnectionpoint

andpowerswitch.

2019

Figure2c:Thebackfaceoftherobot.Thetetherconnectionpointisshowncentrewiththepowerswitch

totheright.

PalletRunResults

Intotal,12uniquepalletrunswereattemptedincludingrunsinthetop(3),middle(5)and

bottomlayers(4).Inmanyinstanceafullruncouldnotbecompletedduetoobstaclessuch

asbrokenpallets,hangingplasticandbowedboards.Afewrunsonthebottomlayerof

palletsweretestedtoadistanceof7m,howevertherobotcouldnoproceedfurther

beyondthisasadifferentpalletconfiguration(4stringer,asopposedto3)werefoundat

RELEASED

thisdepth–Figure3.Eachofthepalletrunsarelistedbelowdetailingtheobstaclesand

complicationsaswellastheassociatedvideofileaccompanyingthisrun.

BY ARPANSA

Figure3:a)Astackofpal etswherethetopthreehave3stringers,whilstthebottomisa4-stringer

configuration.B)Lookingatthesamestackfromthesidethetopthreepal etshave5baseboards,whilst

UNDER

the4-stringerpal ethas4baseboards.

Allvideofilescanbelockedinthefol owingfolder:

s 33 - security

FOI

VideoResults

FEBRUARY

PalletRun Notes

VideoFile

RunB-2a

Thesecondpalletinhasbeenplacedontopof

B-2a_pallet_robot_2018-

somethingandbrokenabottombaseboard.

05-30-14-40-43

Somepalletswith3baseboardsnot5.

2019

RunB-2b

@5minthereisabrokentopdeckboard(3:15of

B-2b_pallet_robot_2018-

Video)

05-30-10-38-43

@7mapalletwith4stringerboardscouldbeseen

(4:25ofVideo)

Thisrunincludedamixofpalletswith5and3base

boards.Thecurrentrobotconfigurationismorelikely

togetstuckinthe3-baseboardconfiguration

particularlygoingbackwards-whichdidoccurinthis

run(6:00ofVideo)

RunB-3a

AFewrocks

B-3a_pallet_robot_2018-

05-29-13-53-08

Extrapieceoftimberlayingonground–caused

minordifficultiesreversingout

RELEASED 4stringerpallet@7mdepth

Thisrunwascompletedagainwithagammameter

attached(seegraphbelow)

RunB-3b

Thisrunhadasheetofblackplastichangingdown.

B-3b_pallet_robot_2018-

Wepushedthroughokaybuttherobotgotcaughtin 05-30

itreversingout.Toremovetherobotphysical

BY

interventionwasrequiredasacombinationofpulling

onthetetherinco-ordinationwithdrivingthetrack

ARPANSA

forwardandmanoeuvringoftherobot.

RunM-1a Brokenbaseboard@0:18ofvideo

M-

1a_pallet_robot_2018-

stoppedallfurtherprogression

05-30-12-05-20

UNDER

RunM-1b Warped+Brokenbaseboard@0:50ofvideo

M-

1b_pallet_robot_2018-

Narrowedheighttoomuch,couldnotproceed.

05-30-12-05-20

RunM-2a Stuckonthetetherclampreversingout–a4base

M-

board,3stringerpallet.

2a_pallet_robot_2018-

FOI 05-30-12-11-51

Alooseboltwasseensittingonabaseboard

FEBRUARY

RunM-3b Abrokentopboardinthe2ndPalletobstructedthe

M-

path,couldnotgofurther.

3b_pallet_robot_2018-

05-30-14-13-13

RunM-4a Abaseboardbowedupandadeckboardbowed

M-

down.Thebaseboardhaseitherfractured,oris

4a_pallet_robot_2018-

aboutto.Wedidnotproceedfurthergiventhe

05-30-11-57-41

2019

difficultyinaccessingtherobotandtetherifstuck.

T-3b_pallet_robot_2018-

RunT-3b

Noobstruction,butdidnotwanttoproceedtoo

05-30-14-21-33

deepasthetoplevel(withoutaplatform)makesit

difficulttoaccessthetetherandrobotforretrieval.

T-4a_pallet_robot_2018-

RunT-4a

Abrokentopboardinthe2ndpalletobstructedthe

05-30-14-17-01

path,couldnotgofurther.

T-4b_pallet_robot_2018-

RunT-4b

Aslightrisefromonepalletstacktothenext.Didnot 05-30-14-17-01

wanttoriskgettingstuckontoplayeranddidnot

proceedbeyondthispoint.

DepthMappingResults

Alongsidethecameraforvisualinspectionwasatime-off-flight3Dcamera.Multipleof

RELEASED

thesesensorsmaybeusedinfutureplatforms.Incombinationwithothersensing

components,thedatagatheredfromthissensorcouldbeusedtobuild3Dmapsofthe

environmentexploredbytheplatform.

Avideofiletitled

“DepthData.mp4”showsashortclipofaninstantaneouspointcould

gatheredbythiscameraalongsidethestandardvideofootageastherobotmovedthrougha

pallet.

BY

GammaDoseMeterResults

ARPANSA

Duringthefinalpalletrunofthetrip,agammadosemeter(PDS-GO)wasaddedtothe

robotandsentthroughpalletrun,B-3a–therunweweremostconfidenttraversing.The

additionofthissensorcompromisedthemechanicalintegrityofthejoinerbetweenthe

frontandbackhalfoftherobotshence,greatercarewasrequired.Thiswasalsothelastrun

achievableasduringthistestareartrackoftherobotwaslostduetofatigueof3Dprinted

componentsandtrackquality.Ashortclipshowingtheleftbehindtrackisvisiblehere:

UNDER

s 33 - security

titled s 33 - security

GammaDetectionFOI

60

50

FEBRUARY

40

dose

30

rateuR/h

background

se 20

Do 10

2019

0

1

50

99

148

197

246

295

344

393

442

491

540

589

638

687

736

785

Time(second)

Figure4:GraphofthedataobtainfromthePDS-GoDosemeterforonepal etrun–LocationB-3a

FortheresultsseeninFigure4,therobotwasinthepalletsforapproximately14mins,

whichisreflectedbythetimeinsecondonthexaxis.Thisincludedgoingintoandoutofthe

palletrun,thereforetheresultontheright-handsideofthegraphareareflectionofthose

ontheleft.Thespikeseenat99secondsand~760secondswouldhavebeentakenatthe

samedepthintothepalletrun.Atthisstagewithlimitedpositioncontrolontherobotexact

positioncannotbedeterminedbutthiswillbeavailableinthefutureversionoftherobot.It

shouldbenotedthatthetimespentundereachdrumwasnotconsistentormonitored

whichwillaffecttheaccuracyofthedosereadingastimeisrequiredtoobtainstable

accuratereadings.

Overal notes

RELEASED andfindings

QualityofPalletRuns

Mostrunswelookedathadsomesortofcomplicationorinterestingfeature.

- Rocks

(notanobstacle)

- Bolts

(notanobstacle)

BY

- Brokenbaseanddeckboards

(onlyanobstacleifextremebrakeage)

- Warped/bentbaseanddeckboards

ARPANSA

o

(onlyan14minobstacleifsignificantwarpingdecreasedtheheightto<

70mm)

- Hangingplastic

Themiddlepalletrunhassignificantbowingandbreakage,whicheitherlimitsaccess

completelywithbrokenbeams,createslargedrops,ornarrowsthespacebeyondwhatis

UNDER

accessible.Themiddlerunwilllikelyhavethemostdamageandbethemostdifficultto

transverse.Thegroundlayergivesustheflattestsurfacetomoveacross.Thetoplayer

palletswilllikelyhavelessdamagethanthemiddlelayerbutgiventheelevatedheightitis

difficulttoretrieveastuckrobotwithoutanelevatedplatform.

FOI

Accesstotheallotherpallets

Foraccesstotheremainingdrums,duetothealignmentofthepallets,theendwallofthe

FEBRUARY

hangerwillneedtoberemoved.Additionally,theconcreteBundingattheendofthe

hangerwilllikelyobstructtheentrancetothegroundlayerpallets(Figure5).Wewillneed

toinvestigateifwecanremovethisBundingtoachieveaccess.

s 33 - security

2019

Figure5:Bundingattheendofhangerfive.A)showinghowthebundingsitsabovegroundlevelthatthe

palletsareplacedon.B)themetalsheetingoverthebundingandplubingfeturesalongthiswall.

Thegapbetweenthepalletsatdoor5(Figure6)couldbeusedtoplacetherobotintoarun

ifregulatorypermissionisgivenandtherobotisdesignedaccordingly.–i.e.theabilityto

bendtherobot,haveitplacedinassmallersectionsatatimeorthefunctionalitytoturn

underitsownpowerintoeachrun.Thiswouldbeusefulifanyofthefollowingoccur:

1. TheBundingdoesnotallowaccesstothebottomlayerofpallets–orifwecannot

destroyit.

RELEASED

2. Ifwedogetaccessfromtheendofthebuildingbutthereisanobstructionwithina

palletrunandthefullruncannotbecompleted-thegapatbaydoor3could(with

significantengineeringeffort)allowfortherobottodothesamerunfromtheother

direction.

3. Thesecondsetofpalletsafterthegap

maynotbeaccessiblefromtheoriginalset

duetomisalignment–bothverticalandhorizontal.

BY ARPANSA

UNDER

FOI

Figure6:Thesmallgapthatexistsapproximatelynearbaydoor5.

FEBRUARY

However,thereislikelyasignificantsafetyissueforpeopletoaccessthisspaceand

manuallyplacetherobot,participiallytoreachdeeperpalletruns.Effort

couldbespent

deigningarobotwhichcoulddriveitselfdownthislocationandturnintoarun,butthisis

accompaniedwithsignificantcomplicationstothedesign-articulatedsections,pulleyson

tethersetc.Thiswilllikelyonlybeconsideredafterfirsttestingthemoreachievablerigid

bodydesigninthissectionofpallets.

2019

Differentpalletconfigurations

Itwasdiscoveredthroughtestingthatthereareanumberofdifferentpalletconfigurations

withinthehanger.Therepalletsdonotappeartobeorderedorplacedinanyspecific

locationthefollowingconfigurationshavebeenfoundsofar.

1. 3stringer–5baseboards

2. 3stringer–3baseboards

3. 4stringer-3baseboards.

The4stringerpalletsaddcomplicationastheyhave3runsperpalletasopposedtothe2in

a3-stringerpallet(Figure3).This4-stringerpalletbecomesparticularlydifficultifitis

alignedwitha3-stringerpalletasthechannelwidthavailablefortherobottotransverseis

cutdownto150mm s 33 - security

Theotherconfigurationwhichprovedchallengingfortherobottotransversewasthe3-

stringer,3-baseboardconfiguration.Thiswillbeeasilyrectifiedinthenewdesignasthe

robotwillbesectionedsothatnoonelengthislessthanthelengthbetweenthesebase

RELEASED

boards.

Robotcontroloptions

Thetetherprovidedtobeagoodcontrol/poweroptionforthepalletrobotasitisgoing

intoextremelydifficulttoreachplacesandoccasionallyneededassistancetoberemoved

BY

fromtheselocations.Therefore,thetetherprovidestheabilitytopullbackandretrievethe

robot.Additionally,giventhelimitedsizethereisnoroomforon-boardpower.

ARPANSA

However,afterinvestigatingtheenvironmentthatthetopofdrumsrobotwillbetraversing

itwasconcludedthatthetethercouldprovefarmorecomplicatedforthisscenario.Thetop

ofdrumsrobotwillbemakingmultipleturnswhichcomplicatestheengineeringrequired

fortetherdeploymentsystems.Additionally,therecouldbethepotentialforthetetherto

dropdownbetweenbarrels,particularlythosearoundtheedgeswhichcouldcausesafety

UNDER

hazard.

s 33 - security

FOI

FEBRUARY

CollaborationwithAntso

Oneoftheprojectpartnersworkingondetectiontechnologiesforthisprojectisthe

AustralianNuclearScienceandTechnologyOrganisation.Throughdiscussionwithstaffon

siteduringtheMayfieldtrip,thereissignificantpotentialtotakesomeoftheirprototype

sensingequipment,specificallythescintillatordetectorsandmountingtheseinourrobotic

platforms.Thispotentiallyincludesthelow-profilepalletrobot,dependingonfinalsizeand

2019

configuration.

Additionally,givenCSRIOData61’sexperiencewith3Dmappingthereisawealthof

knowledgeinthisareawhichcouldbesharedwiththoseworkingontheANSTO

technologies.ANSTOstaffonsiteexpressedinterestinincorporatingstationarylaser

scanningintotheirgammadetectionsystemwhichData61staffcanassistwith.

TechnicalLearningforPal etRobot

Thereweresignificanttechnicallearningsgainedthroughtestingthepalletrobotthrough

theenvironment.Thesearemostlyincludedherefordocumentationpurposeandinsight

intotheengineeringworkweplantoinvestigatebetweennowandthenexttrip.These

ideasarenotaguaranteeforwhatwillbeincludedintheproceedingdesignsbutitdoes

showwhatinformationwewereabletogatherfromthistrip.

RELEASED

Sensing

Whilstthisproductwasdesignedasaminimalviableplatformwithlimitedsensing,the

learningsfromthistriphavehelpedshapethedirectionandrequirementsofthosesensing

modalitiesweplannedtoincludeforfuturetests.

• Morecameras:

BY

o Lifecamfrontandbackfornavigation–includesautofocusandbrightness,

ARPANSA

bothusefulfeatures.

o Upwardanddownwardfacingcamerafordruminspection.Wideangle,close

rangefocus.

• MultiplePicoflexdepthsensors?

o needtoconfirmifthisdataisgoodforreconstruction

UNDER

o AlternativelylookatOuster(https://www.ouster.io/)LIDAR.However,itis

verylargefortherobotformfactor.(80mmx63mm)

• Morelights

FOI

o ThediffusedLEDsweregoodforclosetomediumrange

o Potentiallygetafocusedhighlumenspotlightforlongdistanceillumination.

FEBRUARY

Thiswouldallowforvisualinspectionfurtherdownthepalletrunevenifthe

pathifblocked.

• LiveOdometry

o Enableanddisplaydistancemeasurementsonscreen(usingPicoflex)whilst

operatingtherobottoconfirmifaspaceisaccessibleornot.

2019

Mechanical

Theprimarypurposeofthisexcursionwastotestthemechanicaldesignofthethrough

palletrobot,themoremechanicallycomplexofthetwoproposedsystems.Alargeamount

waslearntandwillbeimplementedtofurtherrefinethedesign.

• Makeitevennarrower

o ~140-150mmwidetoensureitcanmovethrough4stringerpallets.

o Putthemotorswithinthetrackstoenablemorespaceforsensorsinternally.

• Makeitlonger

o Slightlytooshort.Currentlyonesectioncannotbridgethedistancebetween

baseboardsona3-baseboardpallet.Whichenabletherobottodipintothe

gapsandpotentiallygetstuck.

• Cooling

RELEASED

o Voltageregulatorisgettingveryhot.

o Copperheatsinks+heatsinkepoxy.

o Thestainlesssteel(requirediftherobotwheretoundergochemical

decontamination)isaverypoorheatconductorandthereisnoactive

cooling.Theexclusionofactivecoolingisintentionaltolimittheintakeof

dustinternaltotherobot.

BY

• Trackmaterialandquality

ARPANSA

o Thesetoftracksusedonthebackhalfwereoflowerqualityandcausedfar

moreproblems(trackslippage,couldn’ttensionthemeasily)thanthefront

higherqualitytracks.

• Tetherattachmentdesign

o Thetetherclampusedtoprovidestrainreliefprotrudedtoofarbeyondthe

lengthofthetracksandwouldcausingjammingoftherobotagainstapallet.

UNDER

• Haveaskidplateonthebackbaseoftherobot,adesignsimilartothefrontof

robot.

• Needtoreconfigurethetetherinputlocationastherearfacingcamerawillneedto

FOI

becentred.

• Generally,moreoftherobotwillbemachinedandnotmadeof3Dprintedparts.

FEBRUARY

Particularlysectionslikethetrackrollersandwheelswhichareundertension.

• Rigidorarticulated?

o Weareundecidedwhethertokeeptherobotrigid,ortoarticulatethe

sectionsbetweeneachtracklength.Rigiditysimplifiesthecontrolbutlimits

theabilitytoturn.Mayalsogetwedgedwhensignificantrisesandfallsare

found.

2019

o Testingrequired.WillstartwithRigid.Farsimplercontrol.

Control

• Someonboarddatalogging

o PotentiallytheUPboard

o RunningaROScontrolnodeloggingdataonboard.

o Limitstheamountofdatarequiredtostream.Lendingitselftobetterdata

integrity.

• PotentiallyuseFibreforcommunication

o Lightweight(50-60mlength)

o Unlikelywewillhitbandwidthissues.

RELEASED

• Motors.

o morepower.

• Encoders

o Duetolastminutecomponentfailure,DCmotorshadtobeincludedinthis

porotypewhichhadnoencodersandthereforetherobothadnoposition

feedbackandcontrol.

BY

• Autodistancingoftherobotfromsideofpallet.

ARPANSA

o Anicetohavefeaturewouldbetheabilitytoautodistancetherobotfrom

thepalletstringer.

o Orameasurementofhowfartherobotisfromthestringertobetterposition

therobotalongthepallettohelpwithnavigationinnarrowspaces.

UNDER

TechnicalLearningforTopofDrumsrobot

• Wificontrol–asdiscussedabove.

• 3DmappingusingVelodineorSlowrevo

FOI

• AngelfishattachmentforcameraandLIDAR

o Thiswillenableustoseedownbetweenthebarrels.

o Itwillalsomeantherobotcanavoidtheouteredgeofdrumstoensureit

FEBRUARY

won’tcauseadrumtotopple.

• IMUonboard(GM3)

2019